Steam Boiler for Synthetic PET Fiber Products in Thailand

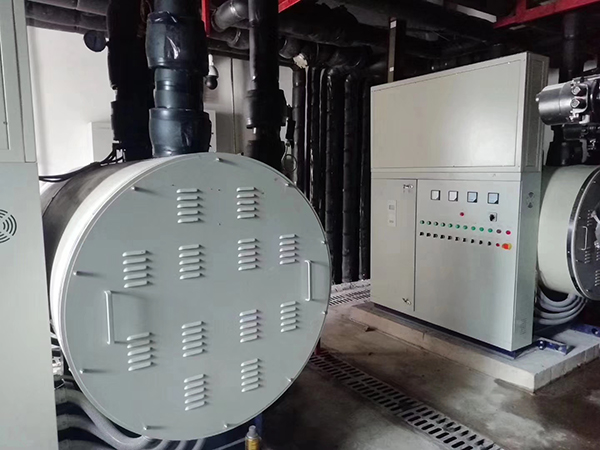

- Project: Steam Boiler for Synthetic PET Fiber Products in Thailand

- Industry: Chemical

- Boiler Type: WDR Series Horizontal Type Electric Steam Boiler

- Boiler Model and Quantity: 2 sets of WDR2-1.25-II

On 30th March of 2021, our client in Thailand paid us deposit for two complete steam boiler systems WDR2-1.25-II powered by electricity, which is used in synthetic PET fiber products. Its steam capacity is 2,000kgs/hr, design pressure is 12.5bars.

For the sea freight was changing every week and going up too much those days, the shipment was delayed again and again. While on June 7 of 2021, we loaded the goods into 1x40’HQ and delivered to our China port, which arrived at our customer’s site before the end of that month.

Synthetic PET fiber products can mainly be categorized into industrial yarn, partially oriented yarn (POY), Spin draw yarn (SDY), polyester staple fiber (PSF), and draw textured yarn (DTY).

The following lists show the applications of various products:

Industrial yarn:

1.Tire cord fabrics2.Airbags

3.Seat belts

4.Geotextile

5.Industrial fabrics

6.Ropes and cables

7.High tenacity dope dyed yarn

Functional fibers:

1.Green fibers2.Multifunctional fibers (anti-UV, anti-bacterial, perspiration absorbing and quick dry fibers, three-in-one fibers)

3.Wavetech Profile fibers (excellent cotton-like texture and handling)

4.Anti-pilling staple fibers (hollow and cruciform)

5.Specialized 4T cross section drawn and staple fibers (able to adjust and improve microclimates within the woven material)

6.Waterproof fiber

7.Dual-colored (mixed color) mélange series

8.Flexible fibers

9.Ultrafine conjugated fibers (sea/island (S/I), tangerine split, sheath/core (S/C), and side by side)

Characteristics of WDR series horizontal type electric steam boiler:

- Electrical parts are made of Schneider, Siemens and other famous brands, with long service life;

- Patented scale alarm technology, monitoring heating surface in real time to ensure boiler safety;

- Heating elements adopt laddering operation, avoiding electric shock to State Grid;

- Timing start or stop, boiler running as you need;

- Real-time monitoring function of water level ensures the normal water level of boiler under various working conditions;

- Electric leakage protection function: when the leakage is detected by the control system, the power supply will be automatically cut off;

- Pressure interlock protection: when pressure exceeds the set value, automatically stop working and give an alarm;

- Black and white instrument water level display, directly showing the boiler water level .

If you want to visit this project on site, or contact our client to check the machine’s work performance, please contact us: WhatsApp:+8613838294337

Electric Steam Generator

Electric Steam Generator

Electric Steam Boiler

Electric Steam Boiler

SZL Series Steam Boiler

SZL Series Steam Boiler

DZL Series Steam Boiler

DZL Series Steam Boiler